General Purpose Current To Pressure I/P Converter

$398.00 Original price was: $398.00.$95.99Current price is: $95.99.

- Loop Power

- Ideal for Pneumatic Control Systems

- IP65 Sealed Case/NEMA 4 type enclosure

- Zero and Span Adjustments for Field Calibration

- 100% Quality Satisfaction

- Uncompromising quality, every time.

- Quality You Can Trust

- Your questions, our prompt answers.

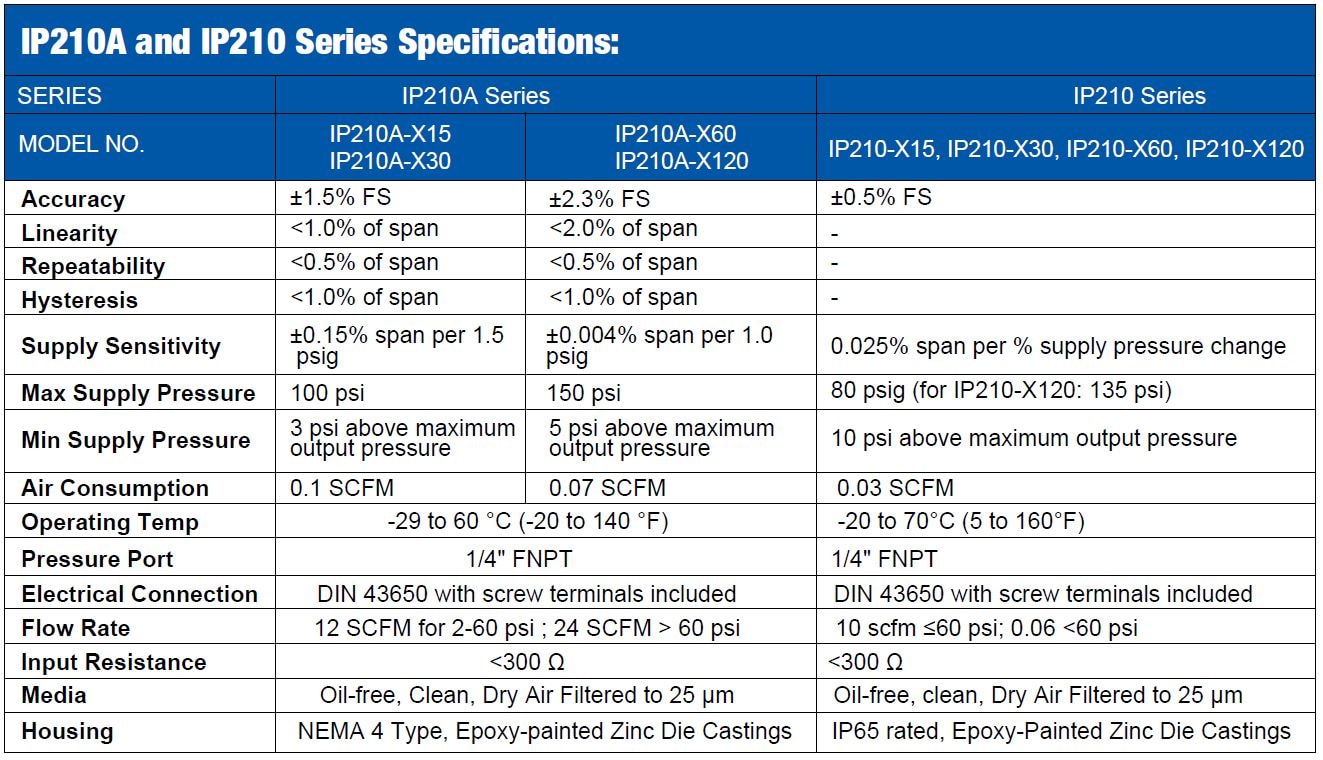

A “current to pressure” (I/P) converter converts an analog signal (4 to 20 mA) to a proportional linear pneumatic output (3 to 15 psig). Its purpose is to translate the analog output from a control system into a precise, repeatable pressure value to control pneumatic actuators/operators, pneumatic valves, dampers, vanes, etc. Both IP210 and IP210A are loop-powered instrument, which eliminates the need for an external power supply (except for IP210-X120).

Principle of Operation

OMEGA’s IP210 and IP210A converts an analog signal (4 to 20 mA) to a proportional linear pneumatic output (3 to 15 psig). Its uncomplicated design and proven electromagnetic force balance deliver consistently high performance.

Both series provides a reliable, repeatable, accurate means of converting an electrical signal into pneumatic pressure. Its force balance principle is a coil suspended in a magnetic field on a flexible mount. At the lower end of the coil is a flapper valve that operates against a precision ground nozzle to create a backpressure on the servo diaphragm of a booster relay.

The input current flows in the coil and produces a force between the coil and the flapper valve, which controls the servo pressure and the output pressure.

Zero adjustment of the unit is made by turning a screw that regulates the distance between the flapper valve and the air nozzle. Span adjustment is made by varying a potentiometer, which shunts input current past the coil. An integral volume flow booster provides adequate flow capacity, resulting in fast response time and accurate control.

| Output Range | 3 to 120 psig, 3 to 15 psig, 6 to 30 psig, 2 to 60 psig |

|---|---|

| Accuracy | 2.50%, 1.50% |

| Input Signal | 4 to 20 mA |

| Connection | DIN 43650 A |

| Pressure Port Type | NPT Female |

| Pressure Port Size | 1/4" |

Be the first to review “General Purpose Current To Pressure I/P Converter” Cancel reply

Related products

Control & Monitoring

Air, Soil, Liquid, and Gas

Control & Monitoring

Control & Monitoring

Microstepping Motor Drives, Analog In/Step & Direction Control

Control & Monitoring

Control & Monitoring

Control & Monitoring

Control & Monitoring

Reviews

There are no reviews yet.